ESAB ®POWERCUT

875 Plasmarc

Flexible heavy duty manual plasma cutting

POWERCUT® 875 is a very powerful plasma cutting package in a tough casing, making it suitable for most plasma cutting applications. It cuts mild steel from thin plate up to 32mm, and also cuts aluminium and stainless steel.

Versatile - Perfect for construction work, for production cutting or using in a hire fleet.

-Designed for rugged treatment and outdoor

use

-More performance features than any machine

in its class

-Pilot arc start facilitates starting on painted

and coated metals

-Long-life wear parts and repairable torch

minimises operating costs

-Trigger lock-in for long-cut operator comfort

-Built-in line conditioner – handles poor power

lines

-Auto drag feature allows torch to drag on

workpiece up to 40A. For easy cutting using a

template-Troubleshooting light on front panel

-Special drag nozzle, up to 40A, reduces wear onsumption

-Two different special drag heat shields with

metal feet helps keep the right distance to the

workpiece. Suitable for piercing and heavy

duty industrial use.

|

|

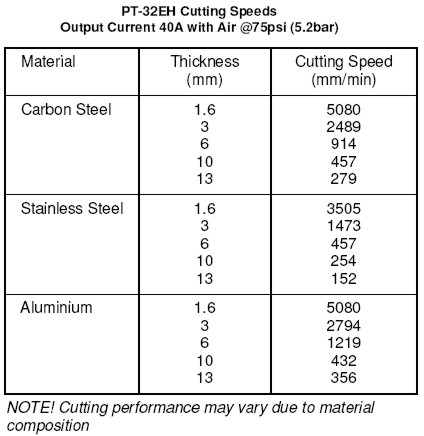

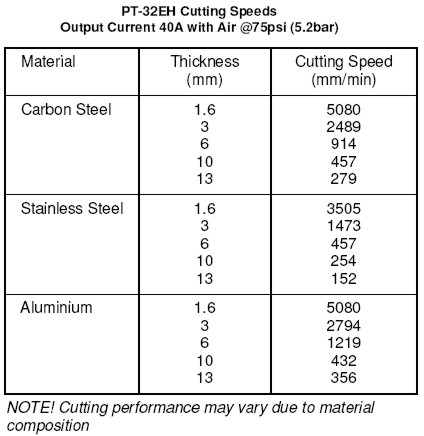

The PT-32EH Torch

The ergonomic torch and the power source have

been designed to optimise performance, with 3

wear parts and increased wear part lifetime. The

result is exceptional - higher production rates at

a lower cost than ever before.

Two switches so the operator can choose the

preferred cutting position. |

|

Technical data

Main voltage

Permitted load at 60% duty cycle(40oC)

Setting range

Open circuit voltage

Power factor at maximum current

Efficiency at maximum current

Dimensions LxWxH

Weight

Operating temperature

Enclosure class

Application classification

Air supply needed

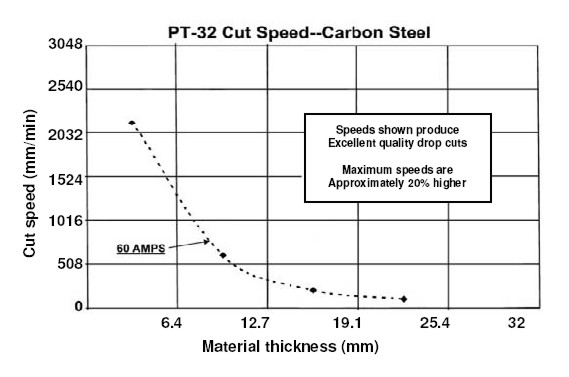

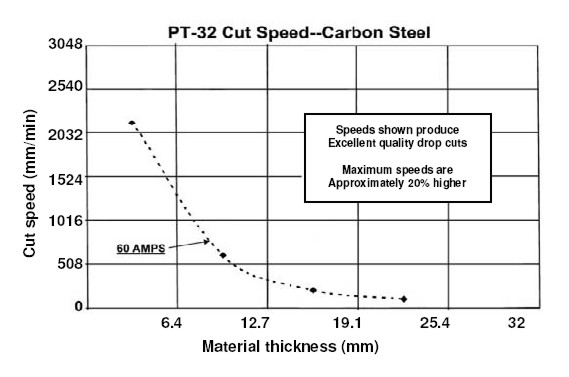

Performance POWERCUT® 875

Mild steel |

POWERCUT® 875

400V and 230V 3~ 50 Hz

60A

20-60 A

275 V

0,92

90%

750 x 318 x 409 mm

39.5 kg

-10 till +40°C

IP 21

S

5,5 bar, 165 l/min

22mm quality / 32mm sever

|

|

|

|

| POWERCUT® 650 shown with PT-31XLPC torch, optional torch wrap, spare parts holder and wheel kit installed |

|

|

The Deluxe torch guide kit for circles of 45 to

1060 mm diameter. Center is fixed by pin,

magnet or suction cup. Also for straight line

cutting. |

Vorige pagina